Monitor your shop floor at a glance

Track machine status in real time and react immediately to disruptions to ensure smooth production flow.

Leverage key performance indicators to anticipate issues and manage your shop floor with confidence.

Support continuous improvement with accurate, reliable production data.

Reliability

Fast and easy-to-deploy interfaces to collect essential production data in real time, such as machine states, alerts, and part counters.

Real-Time Visibility

Access intuitive dashboards with live production data to quickly detect deviations and take corrective action.

Optimization

Measure actual production performance, compare operating speeds, and track KPIs (OEE, OPE, OAE) to support structured continuous improvement actions.

Integration

Shop floor monitoring integrates seamlessly with planning and execution, ensuring automatic data flow without double entry or operational friction.

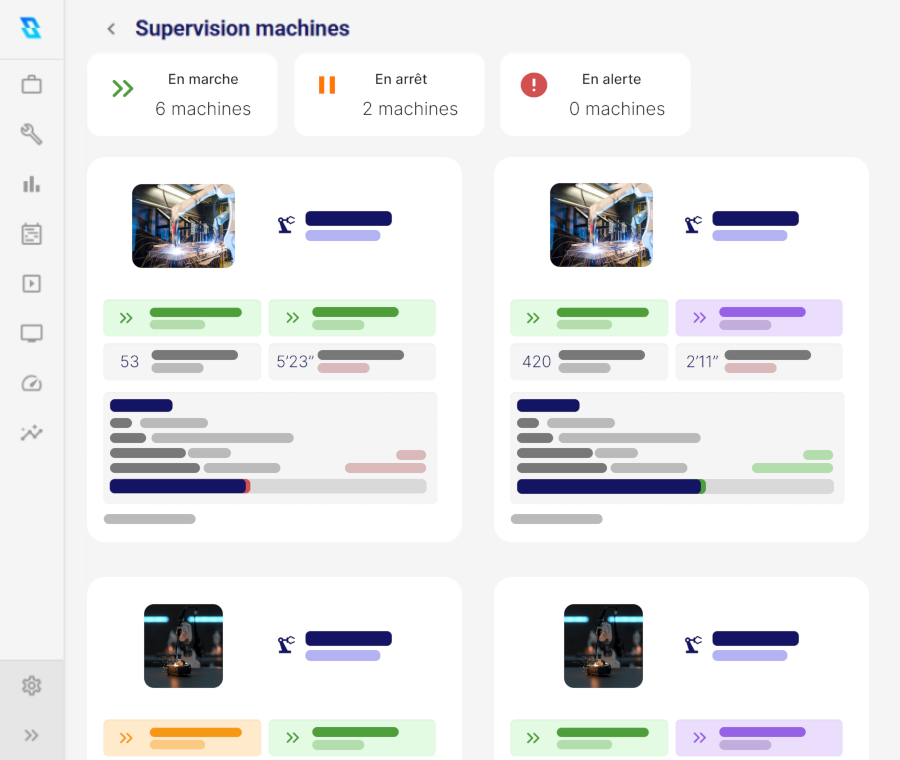

Machine fleet supervision

A direct window into your machines, giving you all the key information at a glance.

Raw and contextualized machine statuses

Part counters and production rates

Simple 24-hour analysis of machine behavior

Access to OPC UA data and raw signals

Ideal for maintenance, industrial engineering, and diagnostics

Production tracking

Visualize your shop floor activity in real time and stay in control of every machine and ongoing operation.

Tracking of production orders and manufacturing steps

Live operation progress

Delay detection and alerts

Actual vs. theoretical production rates

OEE on the current operation

Operation end-time prediction

Linked to the production schedule

Statistical analysis & performance

Gain a clear view of your shop floor performance with reliable, consolidated indicators.

Activity breakdown: production, setup, downtime, etc.

Automatic calculation of OEE and other key performance indicators

Monitoring of indicator variations and trends over time

Detailed activity timeline for each machine

Identification of critical periods and recurring losses

Operational efficiency traceability

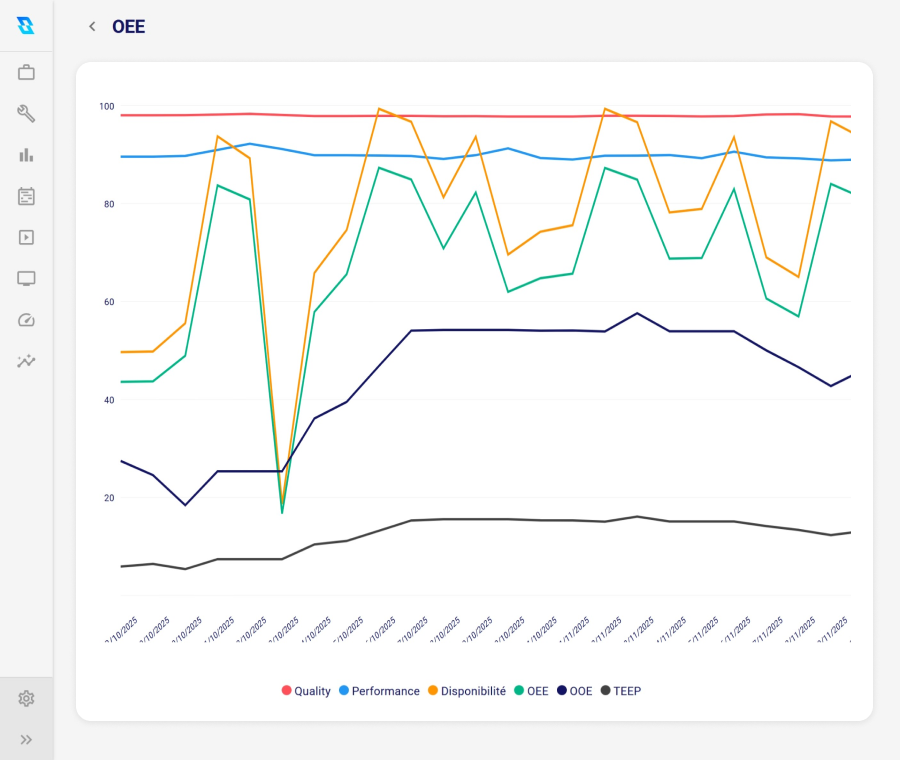

Track the evolution of your key indicators over time to continuously assess your shop floor performance.

Time-based visualization of OEE, OOE, and TEEP indicators

Detailed curves for availability, performance, and quality

Trend analysis: stability, improvement, or degradation

Detection of anomalies and performance breaks

Ideal for continuous management and shop floor reviews

Custom views & TV Display

Share key information on the shop floor and tailor each view to your teams’ needs.

Dedicated TV mode for clear shop floor displays

Views filtered by area, team, machine, or activity type

Real-time updates with no user interaction required

Ideal for visual management and team coordination

Easy customization to match each workstation’s needs

Machine connectivity & automatic data recovery

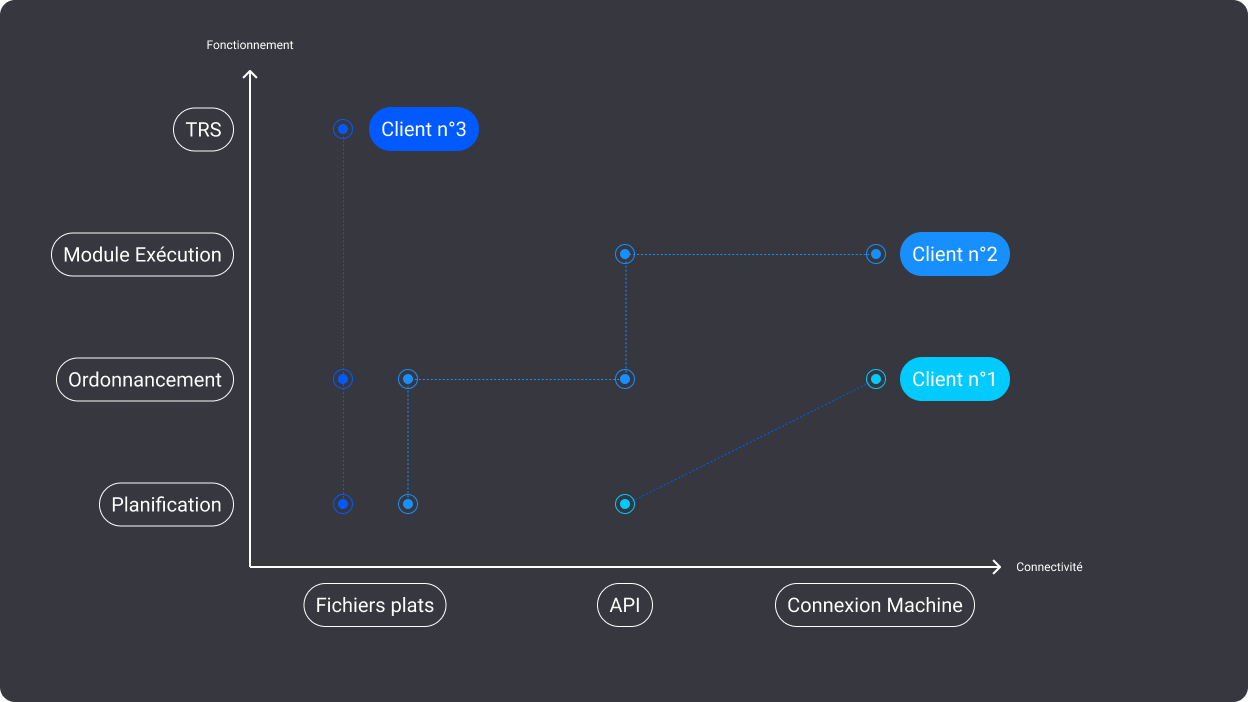

Over the past 15 years, we have acquired in-depth expertise in connecting various types of production machines from different suppliers. Data is automatically collected, consolidated in real time, and displayed in your supervision and analytics views, providing a reliable overview with no manual data entry.

Seamless integration via OPC UA, APIs, IIoT, or Seganto connectors

Automatic machine data acquisition including status, part counters, speeds, cycle times, and alarms

Combines automatic data with operator inputs: downtime reasons, tool changes, and validations

Robust, secure data collection built for industrial environments and 24/7 operations

Planification & Scheduling

Organize your production, optimize resource utilization and reduce lead times with simple, visual planning and scheduling software.

Plan and allocate tasks

Optimize your workshop workload

React to hazards and prioritize effectively

Test your own production scenarios

Complete your solution with the execution module

Communicate instructions to your teams, while collecting real-time information on production progress for optimized monitoring and responsiveness.

Operator interface

Event tracking

Real-time progress monitoring

A scalable, integrated solution to suit your needs