Simple

Scalable

Planning & Scheduling module

deployed in 2 weeks

Flat files

Simple integration

Hosting

Go further by digitizing your production orders and collecting field data

Close the loop with your workshops and work in your information systems as close to the field as possible. React quickly and make the best decisions for smooth, efficient production.

Execution

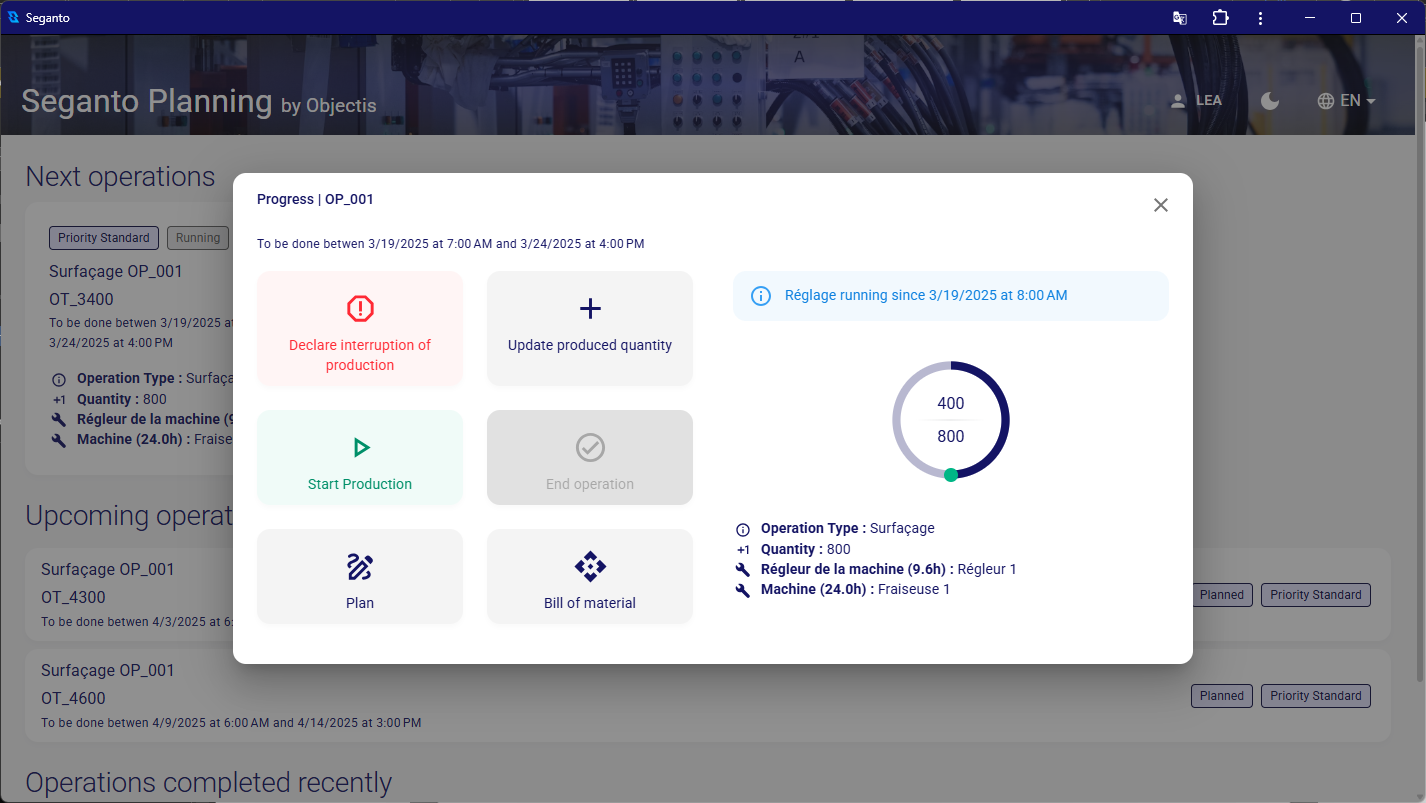

Guide your operators through their activities and get real-time feedback from the field.

Simple – The right information at the right time, in the right format

Responsive – Real-time event detection for decision-making and reaction

Clear – The production targets to be reached are clear to all

Supervision & Analytics

Use indicators to assess your production performance and achieve operational excellence.

Reliable – Consolidated and contextualized data for precise indicators

Instantaneous – Performance monitoring at all times and drift detection

Tracking – Backup production events for analysis

Full integration into your IT ecosystem for real-time synchronization

No more re-keying or information silos: Seganto offers you seamless connectivity for optimized management and real-time decision-making.

Seganto is interoperable with other software such as CMMS, MES, SPC or EDM, enabling you to complete the functionalities you’re missing, all without disrupting your IT ecosystem.

Connect your machines, the key to fully digitalized production management

A methodology for an efficent start

1. Analysis & framing

Understand your needs with your teams, map processes and define objectives for each stakeholder.

2. Configuration & integration

3. Training & adoption

4. Follow-up & development